Rubber Sheets | What Are the Industrial Applications of Rubber Sheets?

Rubber Sheets

Rubber sheets impact our daily lives and are widely used, often closely tied to the industrial world.

These sheets encompass a range of products used in many scenarios — including general, industrial, and mining applications — and are flexible enough to serve various purposes.

In the industrial world, there are various types of rubber sheets available, which are offered in different lengths, diameters, and sizes for various applications. These sheets are highly elastic and resistant to different weather conditions.

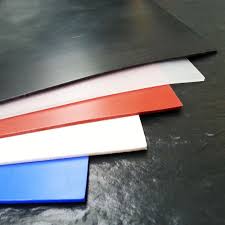

Rubber sheets are also available in black sheets as well as colored sheets for technical and industrial applications. Other general characteristics of rubber sheets include the following:

-

Rubber sheets are chemically very stable.

-

Rubber sheets have no toxic or harmful physiological effects.

-

Rubber sheets are generally resistant to ozone, oxidation, ultraviolet light, and weathering.

-

Colored rubber sheets

-

Rubber sheets made from recycled rubber, modified rubber

ورق های لاستیکی از لاستیک های بازیافتی ، لاستیک اصلاح شده

Rubber sheets are diverse and each type is used for a specific application.

For example, neoprene rubber sheets are widely used in the oil, gas, and chemical industries due to their high resistance to harsh weather conditions, durability, high strength, resistance to oil, sunlight, ozone, and other properties.

In some industries, such as pharmaceuticals and healthcare, rubber sheets are used as insulation.

In the pharmaceutical industry, silicone rubber sheets are used. Silicone is a synthetic rubber that can withstand temperatures up to 200°C and is chemically inert.

EPDM Rubber Sheet: The EPDM rubber sheet, made from synthetic EPDM rubber (ethylene propylene diene monomer), is suitable for outdoor use.

This is because it has high resistance to steam, chemicals, and ozone. Additionally, these sheets possess good electrical properties and permeability.

Rubber sheets are also used as permanent flooring in certain places like children’s play areas, gyms, or car dealerships.

Thin rubber sheets are used to create certain types of mouse pads, and medium-sized rubber sheets are used as car floor mats.

Thick rubber sheets, in industrial settings, may be placed under machinery to reduce noise and vibration.

Conveyor Belt

The conveyor belt is also one of the most commonly used rubber sheets that are now employed in production proce

sses and industries with high-speed machines, offering excellent efficiency.

Use in Production Process

In the production process, when there is a need to move large and heavy industrial and agricultural materials, mechanical devices like conveyor systems are required to move goods with minimal effort.

Role of Conveyor Systems

In general, conveyor systems play an important role in facilitating production and distribution processes. However, ensuring their efficiency is crucial.

Conveyor Components

Regardless of whether the conveyor system is motorized, components such as pulleys, idlers, rollers, wheels, and belts (made of PVC or rubber) are also used in its structure.

Advantages of Using Conveyor Belts

One of the most commonly used types of rubber sheets is conveyor belts, which enhance human labor efficiency. The use of these systems in industrial processes has many benefits.

Conveyor Belts Have No Height Limitations

These systems are designed to save time when moving items from one height level to another.

Conveyor belts can be found in shopping centers, supermarkets, airports, and various factories around the world. They help facilitate the transport of people and goods from one location to another.

But how exactly does a conveyor belt system work? Below, you can see the process of how a conveyor belt system works and its main operating methods.

A conveyor device functions like a wide belt that is fixed in a loop. This loop is connected to several rotors, which are powered by motors.

The looped part of the device is what we know as the conveyor belt, and it is typically made of several layers of rubber.

How Conveyor Belts Work

Typically, the belt (conveyor belt) should be placed on two or more fixed wheels known as rotors.

These rotors rotate and cause the belt to move, which occurs due to the belt’s ability to grip the rotors and rotate around them.

Once the wheels start spinning, the belt is also rotated or moved. The rotors cause the belt to move in one direction on the upper side and in the opposite direction on the lower side.

This means that, for the system to operate, all the wheels must rotate in the same direction, whether clockwise or counterclockwise. If the rotors rotate in different directions, the belt will not move, and friction will cause the rotors to stop as well.

Straight Conveyor Belts

Many conveyor belts are direct, such as the ones found in supermarkets.

However, in some cases, we may need to move the load to higher elevations, in which case a direct conveyor belt cannot be used.

When the conveyor belt is required to transfer goods in different directions, cone-shaped rotors are used in the conveyor system’s structure.