Organic vs. Synthetic Rubber | Which One Is More Commonly Used in the Rubber Industry?

Organic rubber, also known as natural rubber, is derived from the sap (latex) of the Hevea brasiliensis tree, a plant native to Brazil. In contrast, synthetic rubber is artificially produced using various types of polymers through chemical processes.

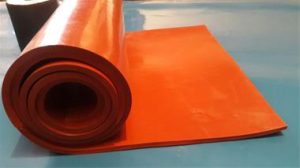

Synthetic Rubber: What Is It Made Of and How Does It Compare to Natural Rubber?

Synthetic rubber is a man-made elastomer composed of polymers derived from petroleum-based products. Today, there are many types of synthetic rubber available on the market.

Some of the most common ones include Styrene-Butadiene Rubber (SBR), EPDM, Nitrile Rubber (NBR), and others. Each of these synthetic rubbers has unique chemical and mechanical properties tailored to different industrial needs.

Both natural (organic) rubber and synthetic rubber offer high tear resistance, good flexibility, and strong tensile strength, making them valuable materials in a wide range of applications.

Advantages of Natural Rubber (Organic Rubber)

One key advantage of natural rubber over synthetic rubber is its higher tensile strength, greater tear resistance, and lower odor compared to IR (Isoprene Rubber).

However, synthetic rubbers generally offer better heat resistance, making them more suitable for high-temperature applications.

Another point to consider when choosing between natural and synthetic rubber is that natural rubber contains naturally occurring proteins, which may cause allergic reactions in some individuals upon prolonged skin contact.

Despite these differences, both types of rubber are widely used in the rubber industry due to their cost-effectiveness and reliable performance.

Rubber manufacturers use both natural and synthetic rubbers to produce parts like rubber diaphragms, rubber bumpers, and other rubber components essential to various industries.

Synthetic Rubber

The characteristics and the pros and cons of both natural and synthetic rubber determine which type is the most suitable for each application—or whether a combination of the two is necessary. For example, automobile tires are made using a blend of natural and synthetic rubber, whereas aircraft tires are manufactured only with natural rubber.

Each type of rubber has its specific use based on its particular properties. Nevertheless, some may prefer the properties of natural rubber over those of synthetic rubber. It has been proven that natural rubber performs better than synthetic rubber in many applications.

However, natural rubber cannot be used for certain purposes. For this reason, natural rubber is generally not widely used in some industries.

?Organic or Synthetic Rubbe

There is no single correct answer to this question, because the choice of rubber type depends entirely on your specific application. In other words, each type of rubber has its own unique properties that make it suitable for certain specific uses.

While natural (organic) rubber may outperform synthetic rubber in some applications, it cannot be engineered to behave in certain ways that synthetic rubber can.

In situations where both types of rubber may be suitable, the final decision often comes down to cost considerations.

Natural rubber is generally more expensive than standard-grade synthetic rubber, meaning that parts made from natural rubber may cost more to produce.

.As a result, most manufacturers prefer to use synthetic rubber over natural rubber