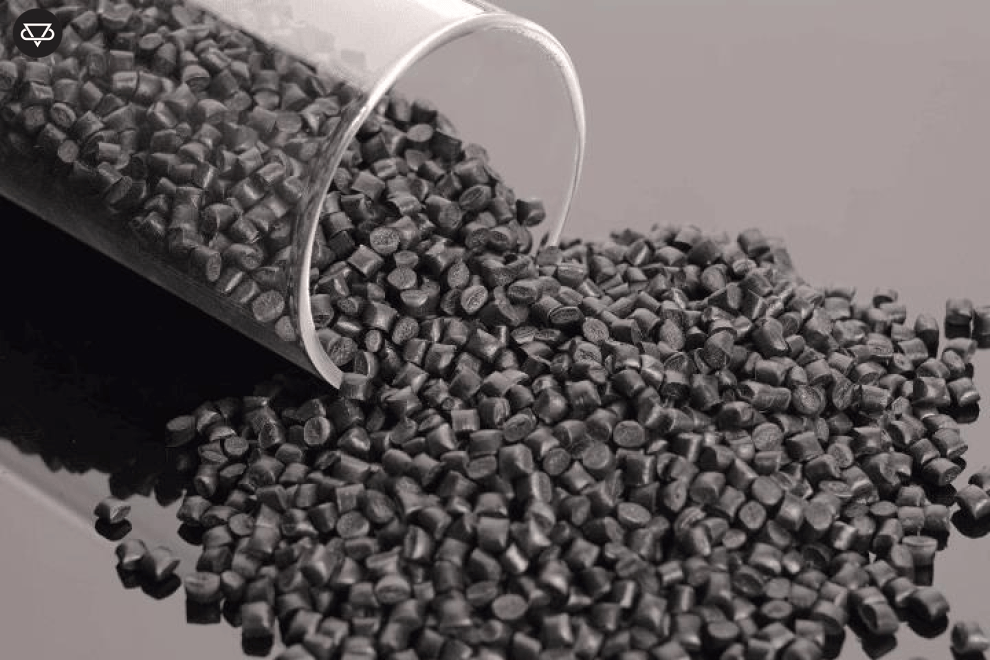

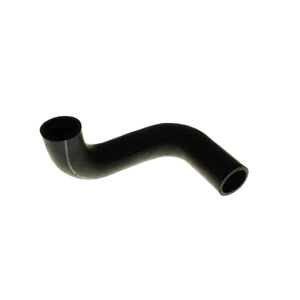

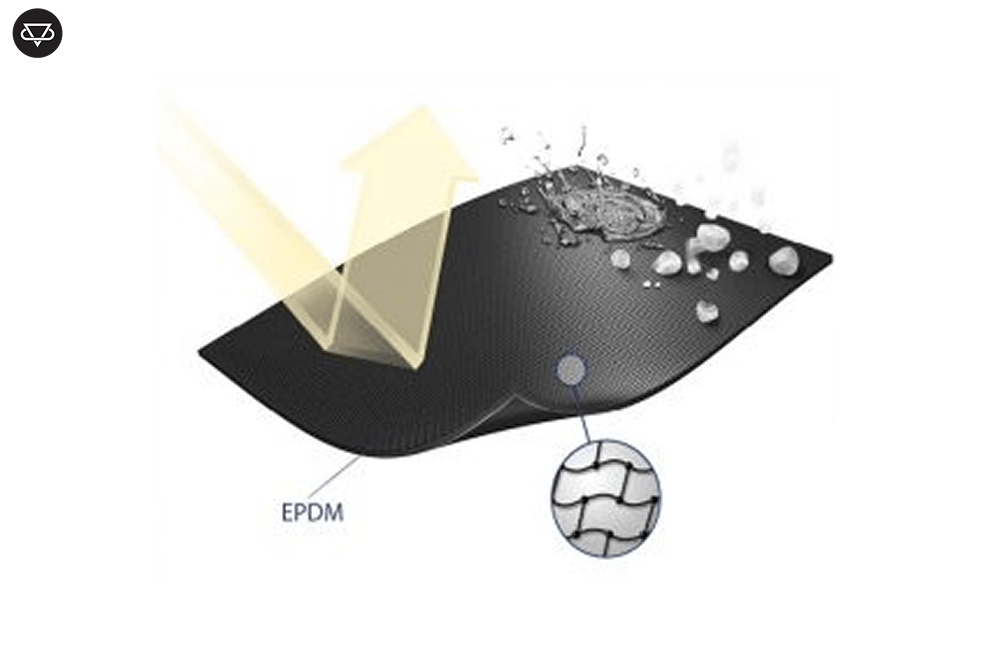

Ethylene Propylene Diene Monomer – EPDM Mel Artistic and Industrial Rubber Company, with its years of experience and expertise in the field of formulating ethylene propylene diene monomer (EPDM) rubber compounds, as well as having a specialized and experienced staff, is ready to provide advice on formulating EPDM rubber compounds to esteemed applicants.

Ethylene Propylene Diene Monomer (EPDM) Rubber Ethylene Propylene Diene Monomer (EPDM) is a type of rubber compound that has the properties of natural rubber and has a high degree of elasticity and resilience, so that it can return to its natural state without undergoing permanent deformation.

What are the goals of the combination?

Rubber compounding or ethylene propylene diene monomer compounding usually pursues three main objectives, which are as follows:

Controlling the rheological behavior of the rubber

Improving the physical, mechanical and dynamic properties of the rubber

Controlling the cost of the rubber

Measurable physical, mechanical and dynamic properties of the nitrile rubber compound formulation

Hardness

Tensile strength

Percent elongation

Compressive strength

Thermal resistance

Chemical resistance

Ozone resistance

Other tests

What is the concept of Mastication in the rubber compounding process?

If we were to provide a definition of mastication, we could say that mastication refers to “putting an elastomer under tension in order to reduce the molecular mass and create viscosity (thickness) in the product with the aim of improving the mixing and quality of the ethylene propylene diene monomer compound.” Mastication in the production of ethylene propylene diene monomer compounds can be done in two ways:

Physical Mastication

Chemical Mastication in Compound Formulation (Using Peptizers)

A raw elastomer can never be used alone because raw elastomer cannot be processed on its own and is resistant to mechanical processes. This resistance to processing is known as “Nerve”. The higher the Nerve content of a rubber, the more difficult it is to process. In fact, Nerve means spending time and energy on rubber processing, which means more cost in the process of producing ethylene propylene diene monomer or ethylene propylene diene monomer compound. We try to reduce the Nerve of the rubber by various methods at the beginning of the work so that we can add additives in greater quantity and quality to the raw elastomer.

What is the elastomer in the formulation of ethylene propylene diene monomer?

An elastomer is actually a polymer that has high elasticity. The name elastomer is made up of two parts “elasto” (derived from “elastic” meaning elastic) and “mer” (derived from “polymer”).

Types of elastomers in the formulation of the ethylene propylene diene monomer compound

Natural elastomer (NR)

Synthetic elastomers

SBR means styrene-butadiene rubber

BR means butadiene rubber

NBR means nitrile butadiene rubber

EPDM means ethylene propylene diene monomer rubber

Silicone

CR means chloroprene rubber

IIR means butyl isobutylene isoprene rubber