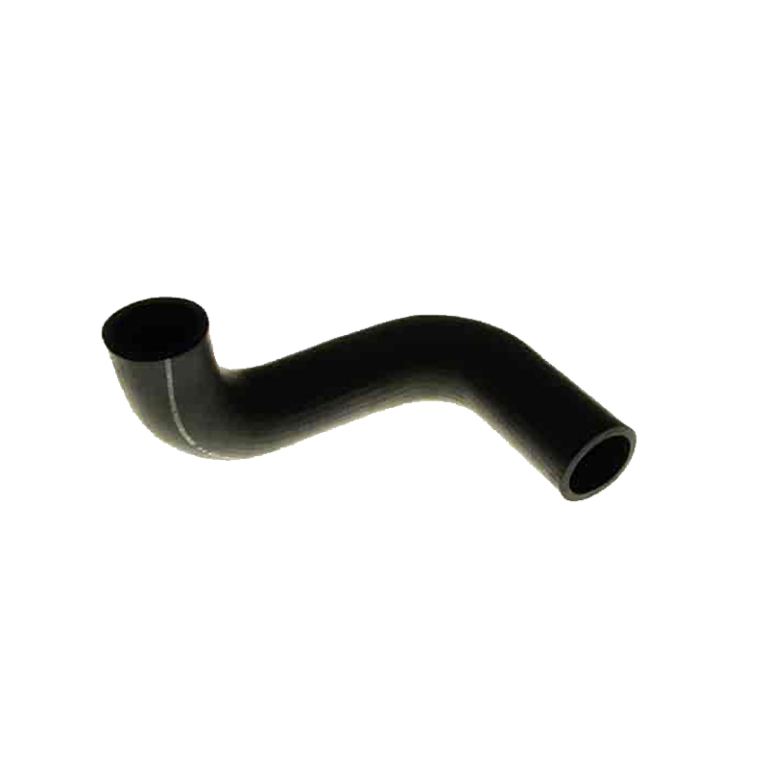

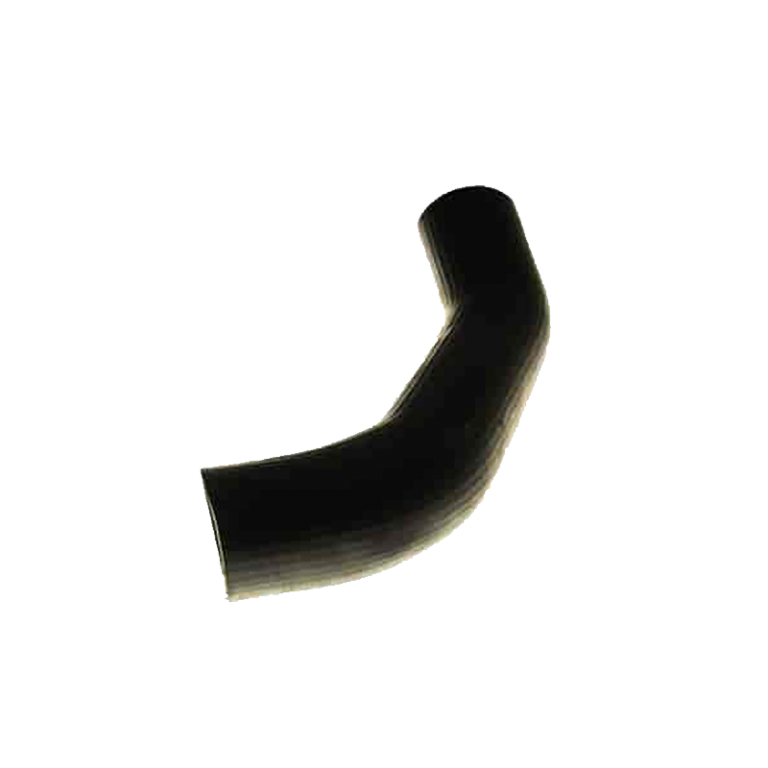

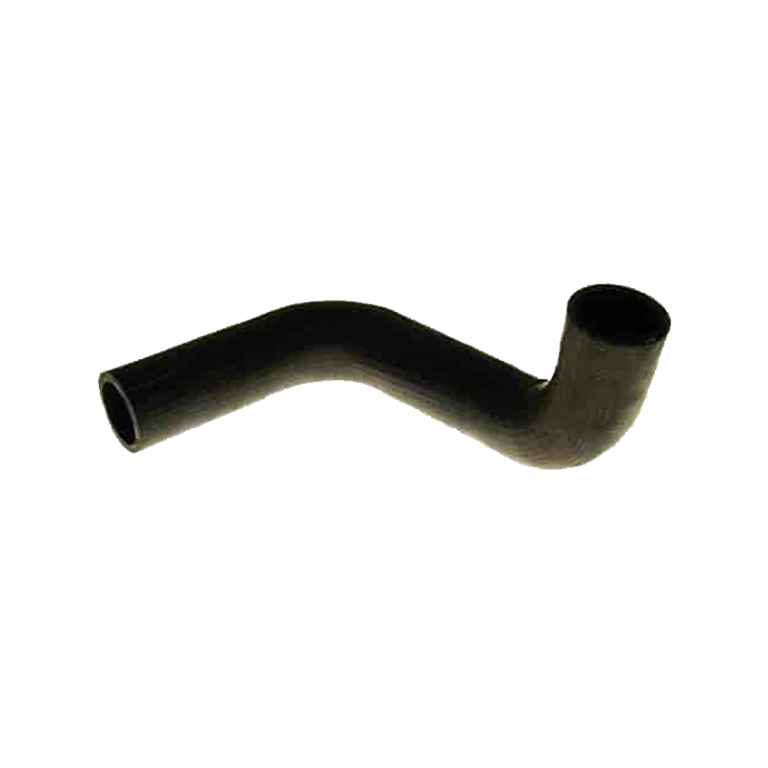

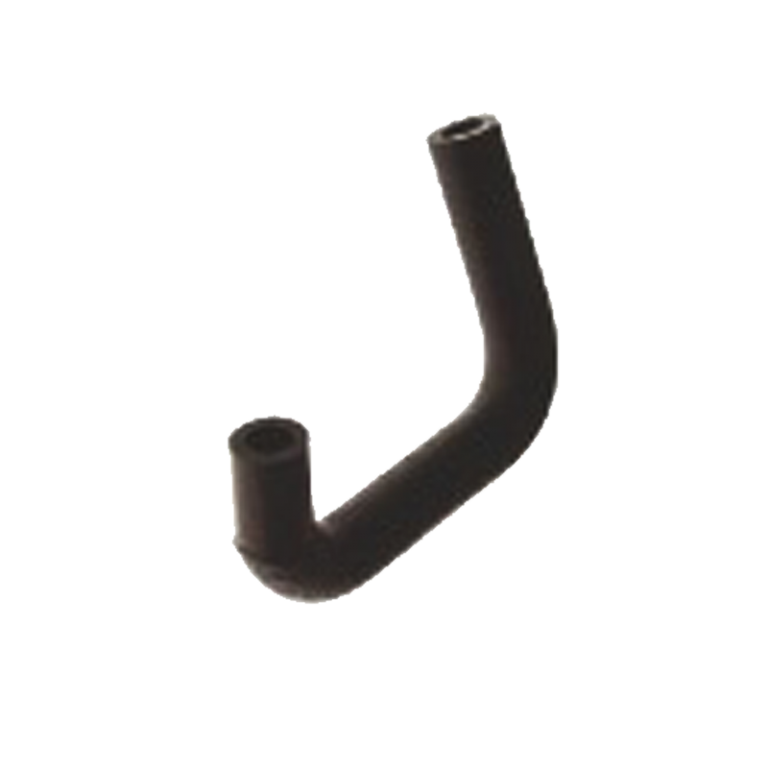

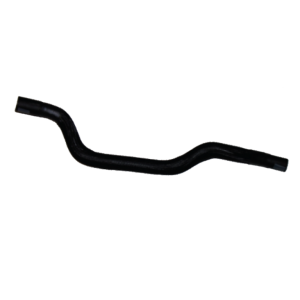

Description

Material of the Right Heater Hose – Pride Injector

(Raw Materials Used in Manufacturing the Right Heater Hose for Pride Injector Models)

This hose is produced in two material classes: EPDM (high-quality) and SBR (standard quality).

The reinforcement yarn used in this hose is a 600-filament polyester.

The key role of this polyester yarn in the structure of the hose is to prevent leakage and water loss, and also to provide antifreeze properties for this specific heater hose.

Service Life of the Right Heater Hose – Pride Injector

The service life of the right heater hose in Pride injector models depends on the type of material used:

-

EPDM-based hoses typically last around 4 years.

-

SBR-based hoses have a shorter lifespan, generally around 6 months to 1 year.

Signs of Wear in the Right Heater Hose – Pride Injector

(How to Detect a Faulty Heater Hose)

Common signs of deterioration include:

-

Surface cracking:

Cracks visible on the exterior of the hose indicate aging and brittleness. The deeper and more frequent the cracks, the more worn-out the hose is. -

Bulging or swelling:

Uneven swelling on the surface signals internal damage or pressure-related stress. -

Peeling or delamination (“double-skin” effect):

This means the hose layers are separating, often due to poor-quality material or aging.

If any of these symptoms are present, it’s strongly advised to replace the hose as soon as possible.

Consequences of Heater Hose Failure – Pride Injector

One of the most serious outcomes of a failed heater hose is coolant loss, which can lead to:

-

Overheating of the vehicle’s wiring and electrical components

-

Potential head gasket or cylinder head failure due to low coolant levels

-

Hot coolant leakage into the passenger cabin

In simple terms:

If the right heater hose is damaged, boiling radiator fluid could splash onto front-seat passengers, causing significant danger and discomfort.

How to Identify a Good vs. Bad Right Heater Hose – Pride Injector

(Quality Inspection Tips)

-

Surface look and feel:

EPDM hoses generally have a smooth, shiny, and polished surface.

In contrast, SBR hoses have a dull, non-glossy appearance. -

No surface defects:

High-quality hoses are free of pitting, bubbles, or delamination (“double-skin” effect). -

Smell test:

If visual inspection isn’t possible (e.g., low light), smell the hose.

EPDM hoses emit a sweet, clean rubber smell, while SBR products typically lack this.

Reviews

There are no reviews yet.